Collection: High-speed centrifuge

Spare parts for high-speed centrifuges: rotors, lids, seals, shaft supports, sensors, motors, control boards, pulleys, belts, original and compatible safety components.

Search for the brand and model of your high-speed centrifuge to quickly identify the correct spare part. If you have any doubts, send us a photo of the rotor or the identification plate.

Guide to high-speed centrifuge spare parts and maintenance

Main available components

The catalog includes original and compatible spare parts for high-speed centrifuges: balanced aluminum or steel rotors, safety lids and closures, durable seals and O-rings, shaft supports, high RPM motors, speed or temperature sensors, pulleys / belts, control boards / timers / digital panels, components for ventilated or air cooling, protection and safety systems.

How to choose the right spare part

- Brand, model, and serial number: this information helps determine rotor diameter, type of attachment, maximum allowed RPM.

- Rotor material: steel, aluminum, anodized; affects weight, heat dissipation, and mechanical resistance.

- Seals and safety closures: must be certified for pressure and stress, especially in lids for high-speed centrifuges.

- Motor and shaft supports: check power, supported RPM, power supply system (single-phase/three-phase), appropriate bearings.

- Electronic boards and sensors: modern systems have RPM control, protection against opening during rotation, temperature sensors; defective parts can compromise safety and performance.

Recommended maintenance

- Clean the rotor and lid after each use to avoid material buildup that unbalances the system;

- Always balance the rotor load (tubes / samples of similar weight) to reduce vibrations and wear;

- Periodically check seals and closures, replacing them if they show signs of deformation;

- Ensure that the motor and bearings operate without unusual noises or play;

- Replace pulleys / belts if they slip or appear worn, to maintain correct speed and safety.

Common problems and possible solutions

- Strong vibrations: unbalanced rotor, irregular weight in samples, damaged supports;

- Lid that does not close or leaks: worn seal, deformed attachments, incorrect pressure;

- Motor struggling or noisy: worn bearings, unsuitable power supply, excessive load;

- Digital board / display unresponsive: check power supply, connections, and sensors;

- Internal temperature too high: insufficient cooling, blocked airflow.

Quick FAQs

How long does a high-speed rotor last?

It depends on the material, usage, balancing, and maintenance; well-maintained steel rotors can last many years.

Can I use universal / aftermarket rotors?

Yes, if they have identical parameters (RPM, diameter, attachment, material) and compatible safety certifications.

What to do if the centrifuge leaks liquid from the lid?

Check the seal, the contact surface, that the lid is clean and properly closed; replace the seal if it is deformed or damaged.

-

Moulinex Tefal rotating sieve filter set for Frutelia Plus JU3701 ZE3701

Vendor:MoulinexRegular price €10,99 EURRegular priceUnit price / per -

Tefal Seb Cone Blade Squeezer Juicer Centrifuge Elea Duo ZN355 ZN3551

Vendor:TefalRegular price €2,99 EURRegular priceUnit price / per€4,99 EURSale price €2,99 EURSale -

Kenwood filter sieve rotating blade centrifugal JE720 JE730 JE850 JE880

Vendor:KenwoodRegular price €24,99 EURRegular priceUnit price / per€26,99 EURSale price €24,99 EURSale -

Braun juice extractor pitcher glass MultiQuick 3 5 J300 J500 4292 4293

Vendor:BraunRegular price €13,99 EURRegular priceUnit price / per€14,99 EURSale price €13,99 EURSale -

Braun Spout Dispenser Stopper Anti Dripless Outlet Juice Centrifuge J500 4293

Vendor:BraunRegular price €3,99 EURRegular priceUnit price / per€4,99 EURSale price €3,99 EURSale -

CuisinArt lid cover for Compact Juice Extractor CJE500E

Vendor:CuisinArtRegular price €14,99 EURRegular priceUnit price / per€16,99 EURSale price €14,99 EURSale -

Moulinex lid cap juice extractor XXL 1200W Smith JU655H ZN655H

Vendor:MoulinexRegular price €16,99 EURRegular priceUnit price / per€16,99 EURSale price €16,99 EUR -

Moulinex container bowl spout centrifuge Vitae JU2000 JU2100 Plus

Vendor:MoulinexRegular price €8,99 EURRegular priceUnit price / per€7,99 EURSale price €8,99 EUR -

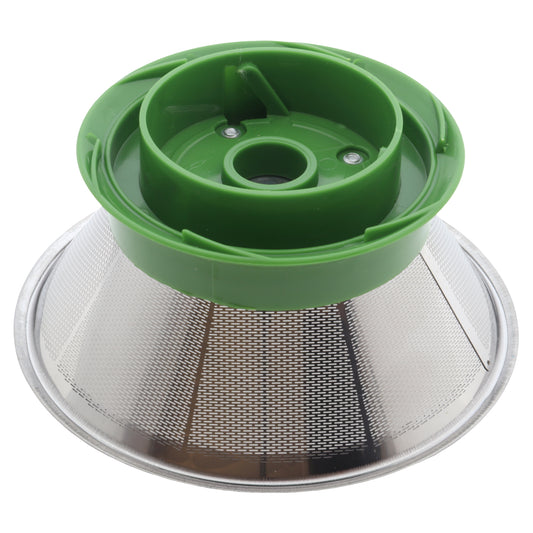

Taurus metal sieve filter green centrifuge 924683 Liquafresh NT-0414

Vendor:TaurusRegular price €13,99 EURRegular priceUnit price / per€14,99 EURSale price €13,99 EURSale -

Philips lid cap cover closure Juicer Viva QuickClean HR1855

Vendor:PhilipsRegular price €53,99 EURRegular priceUnit price / per€49,99 EURSale price €53,99 EUR -

Moulinex Filter Blade Sieve Original For Centrifuge XXL 1200W Smith JU655

Vendor:MoulinexRegular price €18,99 EURRegular priceUnit price / per€19,99 EURSale price €18,99 EURSale -

Moulinex Filter Lama Sieve Centrifuge Extractor XXL JU650 JU650D JU650G

Vendor:MoulinexRegular price €18,99 EURRegular priceUnit price / per€19,99 EURSale price €18,99 EURSale -

Moulinex Presser Pusher Presser Centrifuge Vitae Plus Principle JU20 JU21

Vendor:MoulinexRegular price €5,99 EURRegular priceUnit price / per€5,99 EURSale price €5,99 EUR -

Moulinex Pusher Presser Centrifuge XXL 1200W Smith JU655 ZN655

Vendor:MoulinexRegular price €13,99 EURRegular priceUnit price / per€10,99 EURSale price €13,99 EUR